After winning several major contracts, a leading aircraft OEM knew it faced a challenge in delivering on time and on budget, a situation complicated by rising raw material prices. AircraftCo* believed systemic problems in its supply chain and procurement organization were to blame. AircraftCo asked Bain to diagnose the root causes of these challenges, develop and evaluate alternative organizational structures, identify ways to streamline and improve procurement, and create and execute a communications plan for the new organization.

The Approach

Bain conducted a comprehensive analysis of AircraftCo’s supply chain that led to a strategic redesign. The project began with mapping the value stream (key activities, cost/headcount data) and developing a commodity management fact base for key categories that could be benchmarked against industry best practice. Then the project conducted a full organizational assessment and root-cause analysis of major problems and bottlenecks, and evaluated commodity buying practices. Throughout the process, Bain helped to identify potential quick-win improvements to implement right away, as well deep-dive analyses of potential long-term savings.

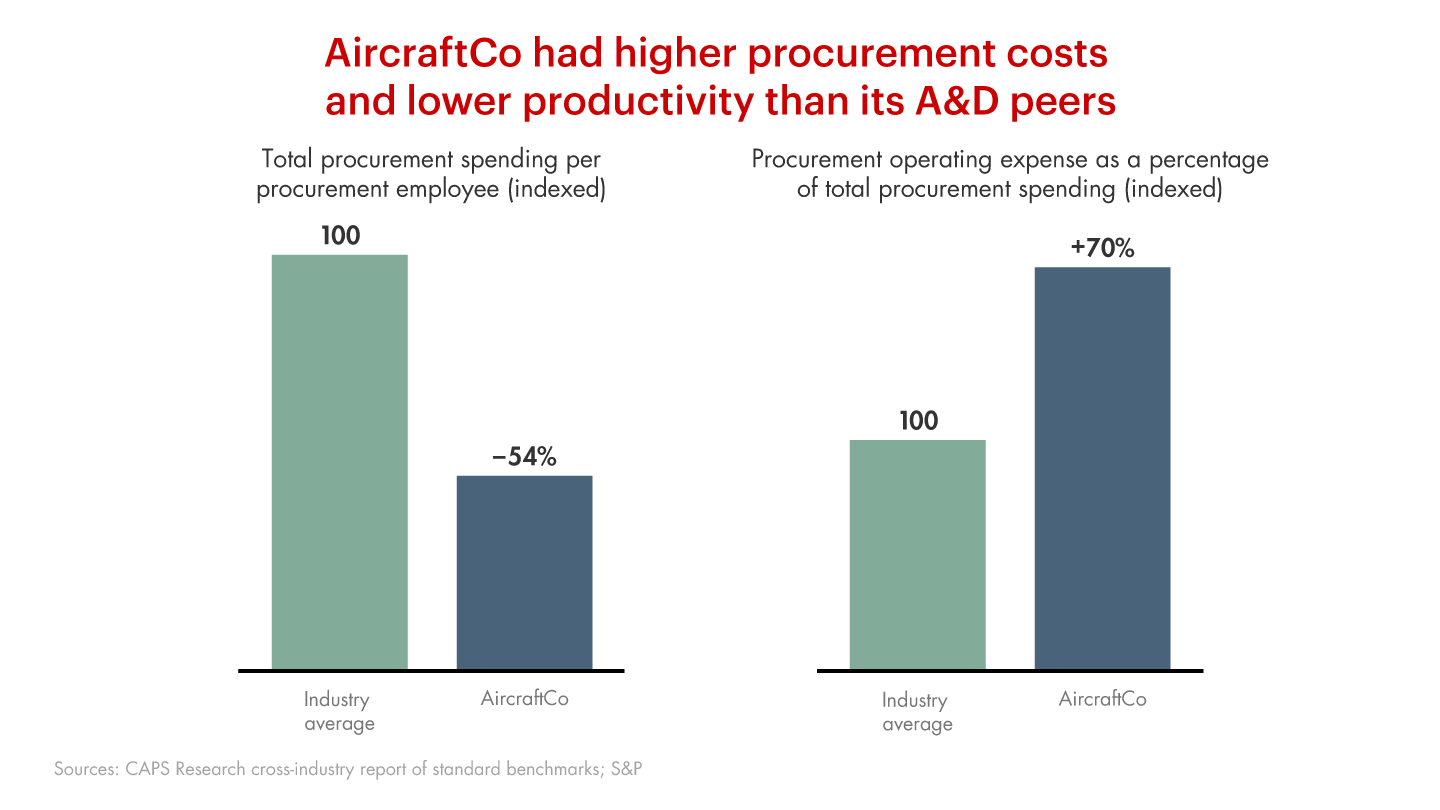

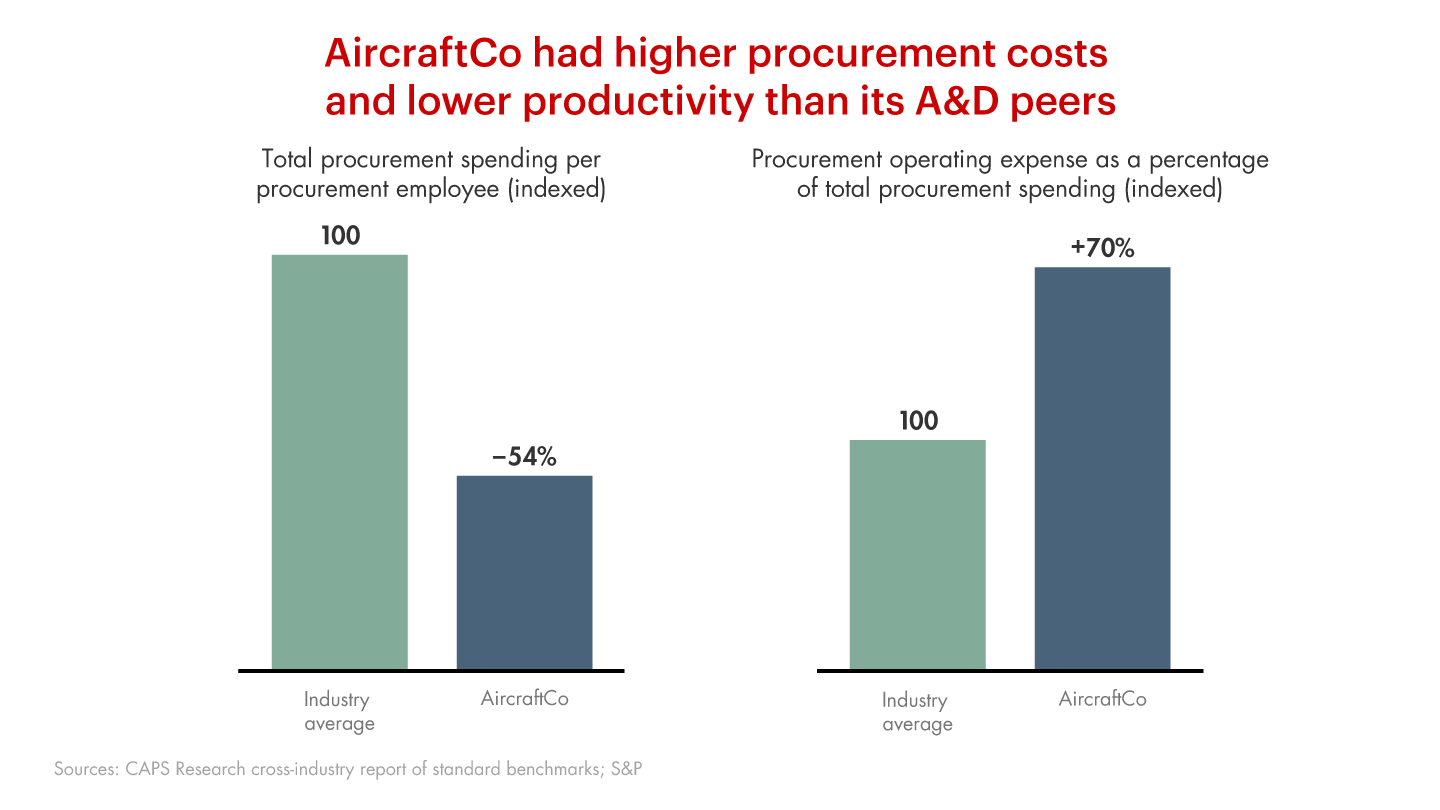

As a result, Bain pinpointed a number of obstacles that were hampering AircraftCo’s performance, including:

- An organizational disconnect between critical strategic sourcing activities and buying-unit decision makers

- Excessive layers of management within the procurement team, and managerial spans of control that varied widely among functions

- Unclear accountability for critical procurement decisions

- Burdensome processes that consumed buyer time and increased costs per purchase to a level far above the industry standard

- A buying organization that lacked the time and skills to perform both strategic sourcing and transactional buying tasks simultaneously

Recommendations

Bain’s holistic assessment of AircraftCo’s supply chain led to a series of recommendations, covering everything from organizational design and talent issues to category strategies and negotiating tactics. Actions focused on improving execution today to meet the business ramp-up, unlocking significant procurement savings, and building the organization’s long-term capabilities. The recommendations included:

- Creating commodity-based buying groups that integrate strategic and tactical buying decisions, with a single “commodity manager” responsible for all commodity purchases

- Filling talent gaps in the procurement organization with high-potential performers from finance and engineering to broaden the skills of the team.

- Boosting long-term contract penetration

- Executing new category strategies to design better work packages and improve contract negotiations to get the most out of vendors

Results

AircraftCo, with Bain’s help, reorganized its procurement organization, streamlined its vendor base, and boosted critical strategic and tactical procurement expertise. As a result, AircraftCo was able to:

- Reduce total procurement costs by 7%

- Cut costs 10% to 15% in key procurement categories

- Shrink its two-year projected procurement headcount by an estimated 50%, which is a reduction of 20% from existing levels

- Achieve a 9% cost reduction for both pending and previously signed contracts

- Increase long-term contract penetration from 25% to 60%

- Close the 10% to 15% gap between actual on-time delivery (OTD) and targeted OTD

- Reduce backlog requirements by 75%

- Within 12 months of engagement, identify 15% of vendors for elimination

* We take our clients' confidentiality seriously. While we've changed their names, the results are real.